FILOALFA Stories Ep. 4 - Robotics3D

An open source robot platform

MARRtino is an open source, open hardware robotics platform that can do autonomous navigation, interact with humans and support them in various domains.

Developed in collaboration with La Sapienza University of Rome, MARRtino is successfully used in various educational activities, ranging from preschoolers to PhDs and post-docs in Artificial Intelligence and Robotics.

MARRtino is designed to be easy to build and easy to program, but at the same time, it uses professional software. Therefore, it is suitable for implementing and experimenting with many typical robotics and artificial intelligence tasks, such as intelligent navigation, human-robot interaction, image analysis, etc.

A robot for every application

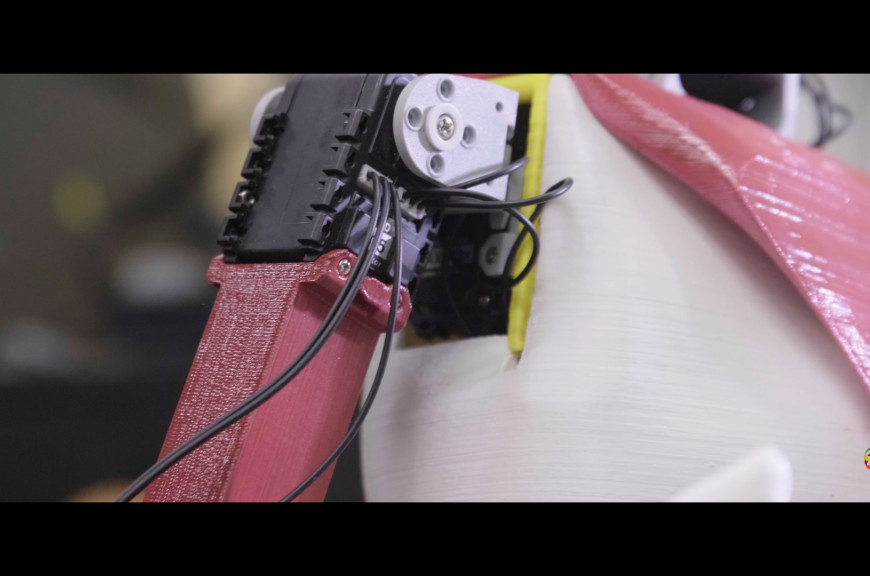

The use of 3D printing and laser cutting has allowed the Robotics 3d team to develop an entire family of robots: from the Robot Waiter, able to serve food at tables, to the Robot Rover, suitable for the exploration of difficult to reach environments, to the Robot Social.

Starting from a common platform, in fact, it has been possible to decline MARRtino in different hardware and software developments. MARRtino Social, for example, allows to interact verbally with humans, provide information and communicate actively. Robotics 3d also developed facial expressions to make the robot more empathetic and facilitate interaction with humans. This has allowed MARRtina to be used in hospitals and with children with learning disabilities to aid in communication and interaction, as the robot is viewed with more sympathy than an adult.

In the agricultural field, the Robot Rover has been integrated into crop monitoring and in particular to check the health status of plants, which may be infested with pests or fungi, signaling the need for human intervention.

But the developments of MARRtino do not end here: being an Open Source and Open Hardware project, MARRtino can also be adapted by the end-user himself, since both the programming and the realization of components and shells can be easily customized.

3D Printing

The prototyping features of 3D printing have made it possible to develop more and more advanced bodies and components over time, adapting the design to the needs of the operation.

The external bodies, for example, have undergone a process of updating in shapes and sizes otherwise impossible with traditional technologies.

The range of FILOALFA® filaments has made it possible to create components with different uses and therefore different characteristics of resistance and aesthetic performance. Robotics 3d has in fact exploited the different characteristics of the filaments to make robots more and more performing and innovative.