Storage and recovery of opened spools

Storage and recovery of opened spools

Does the filament no longer print as it just opened? Have you found a PLA you forgot about in the cupboard and want to know if it will print again? You only need to use a small part of a new filament and you are afraid that the rest will be ruined if you leave it open?

Don't worry, in this article of FILOALFA® Academy we will explain to you how to store the spools in a correct way in time and recover those that have been open for a while and don't print well anymore.

The first enemy of filaments is humidity

If you want to use a filament for a long time, you have to make sure that it does not absorb moisture from its environment.

This is why we explain here how you can best store your spools or what you can do to recover old filament if it has already absorbed moisture.

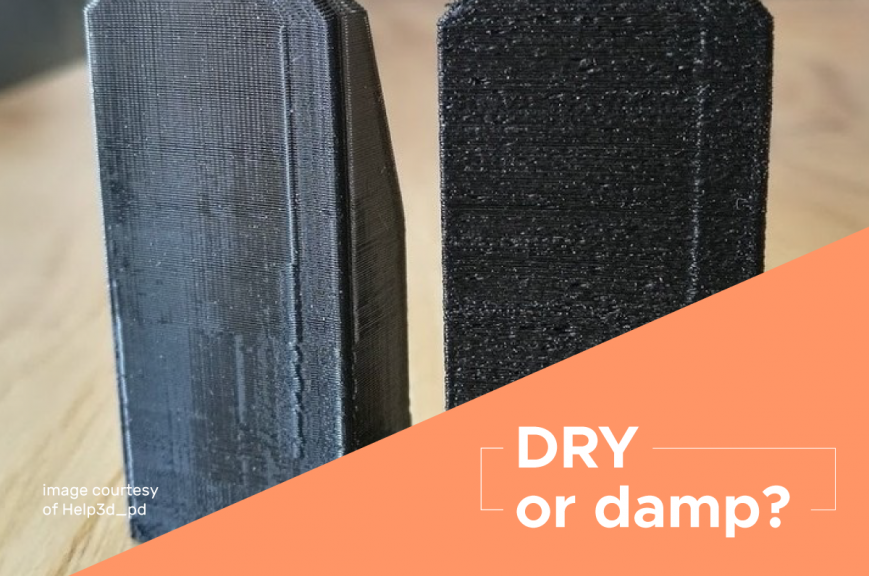

How to tell if a filament is moist

The most common symptoms of a damp filament are:

- Bubbling and popping as it exits the hot nozzle

- Excessive brittleness of the filament when being handled

- Uneven and "jagged" print surface

- In severe cases, fragility of the part and difficulty in extrusion

Depending on the material, moisture can penetrate only superficially or deeper into your filament, and recognizing it is not always easy.

If the moisture is only superficial it usually only causes aesthetic damage to the prints, whereas if the moisture penetrates right to the core of the filament it can cause serious problems to the prints and the final characteristics of the printed object.

Recovering long opened spools

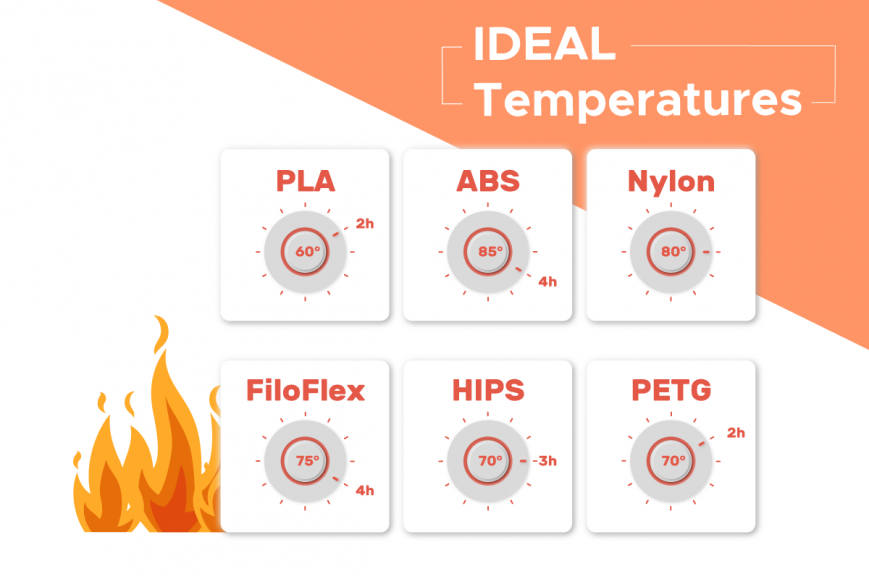

If the spool has been open for a long time and the material is crackling in the extruder, then you can try to dry the filament for 3d printing. FILOALFA® recommends always drying filaments before printing to improve printability, following the data in the table opposite.

Filament drying methods can be various, from the more "hobbyist" to the more professional, here we list the most common:

- Filament dryers: specific devices for one or two spools, they generally allow you to set the power level corresponding to the material to be dried and work autonomously. Many models also allow the filament to be dried directly next to the printer, saving time.

- Food dehydrating machines: designed for fruit and vegetables, they are very easy to find and work quite well in dehydrating filament spools. Just select the temperature and duration of the process and you will have a filament as good as new.

- Oven: Probably the fastest and cheapest method of drying filaments, but also the most inaccurate. By their nature, ovens can reach very high temperatures, and therefore be inaccurate at low temperatures. For this reason, always wait until the oven has reached the set temperature for a few minutes before inserting the spools, otherwise you risk melting the filament. In any case, we recommend using an oven dedicated exclusively to this purpose to avoid contamination with food.

Storing filaments correctly

As you can easily guess the correct storage of a filament after opening the sealed envelope is fundamental.

FILOALFA® always recommends the use of hermetically sealed bags and containers, inserting in the bag a moisture absorber such as silica gel which is supplied with the spool.

There are also vacuum bags and vacuum machines on the market that can make storage even more effective for just a few euros.

There are also plans on Thingiverse for watertight spool holders, which are useful if placed near the printer.

In general, these methods will ensure that your spools are stored properly over time, while also protecting them from dust and UV rays.

Attention to certain materials

At FILOALFA® we dry the granules with the utmost care before transforming them into the filaments you will use in your printer, and we place each spool under vacuum to preserve its purity as much as possible.

However, once the bag is opened, the filament begins its process of moisture absorption (hygroscopy) and gradually loses its original characteristics of printability and strength.

Obviously, there are less hygroscopic materials, such as Polypropylene, HIPS and TPU, and others that are more hygroscopic, such as Polyamide or Nylon, PEEK and PET. For the latter, even a few hours of exposure to ambient humidity can cause problems, which is why we recommend printing the technical filaments in a hot chamber or using special roll dryers.

PLA, PETG and ABS, the most common materials in 3D printing, are among the polymers with low moisture absorption, however they can be compromised after a certain period of time after opening.

Filled filaments, i.e. those materials with added metallics or carbon fibers, also suffer most from hygroscopy, because the fillers act like little straws that carry moisture deep into the diameter of the filament.