The best slicers and their features

What are slicers and how do they work?

You just bought your new 3d printer, you finally found the perfect file for your first creation, and now? What do you do? How do you transfer the model to the 3d printer and print it?

This is where the slicing software, or more simply the slicer, comes in.

The slicer is a software that allows you to literally "slice" your 3d model into various parts. This software creates a series of instructions that the printer will follow layer by layer, depositing the material following a precise path.

But the slicer is not limited to this, it is in fact able to give much more information than the simple "slice": it is also used for example to position the supports for overhanging parts, to change the printing speed and cooling fans for bridges or thin walls, to define the filling of the object and much more.

It is therefore important to know in detail the features and functions of the slicer you are going to use, in order to set the correct slicer parameters.

Which slicer to choose?

There are lots of slicers on the market, mostly free, open-source and compatible with all printers.

Some printer manufacturers have developed their own internal slicer to provide print profiles already calibrated for their printers, but these programs often limit the customization possibilities a lot. One such example is Zsuite, Zortrax's slicer, which allows the printing of perfect models, but dialogues only with the brand's printers.

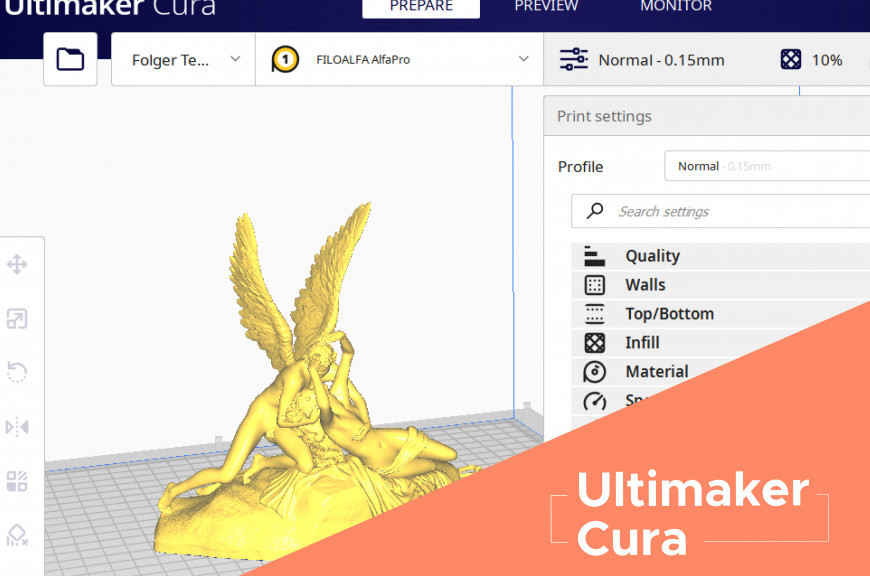

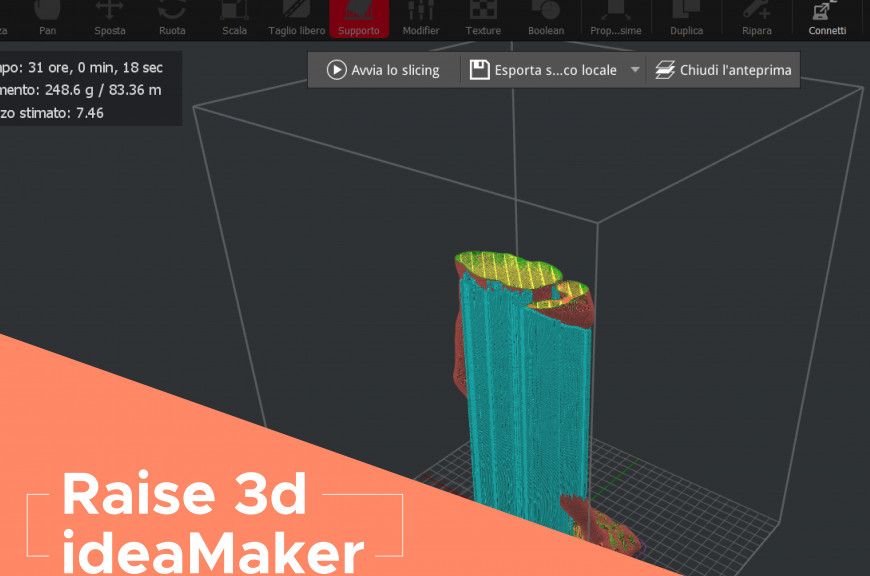

There are also hybrids, such as Cura, Prusaslicer and Ideamaker that are designed to offer the best in combination with the brand's printers (respectively Ultimaker, Prusa e Raise3d), but can also be used with other printers thanks to some adaptations.

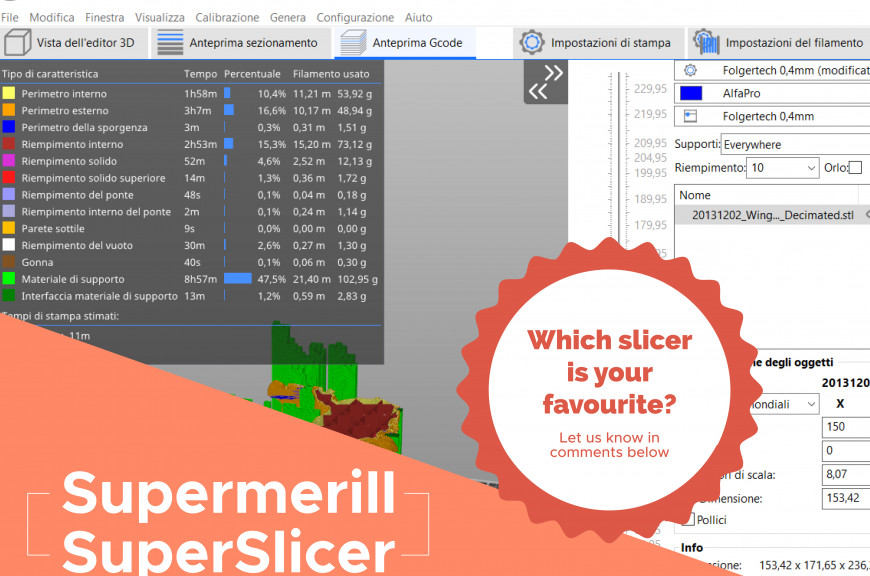

If you want to learn to use software that is suitable for all 3d printers, we recommend using universal slicers, such as Slic3r and SuperSlicer, Repetier Host, or Simplify3d, which are supported by communities of independent developers. The algorithm of these slicers is generally open-source, so they can be customized down to the smallest detail, but may require some experience in learning how they work.

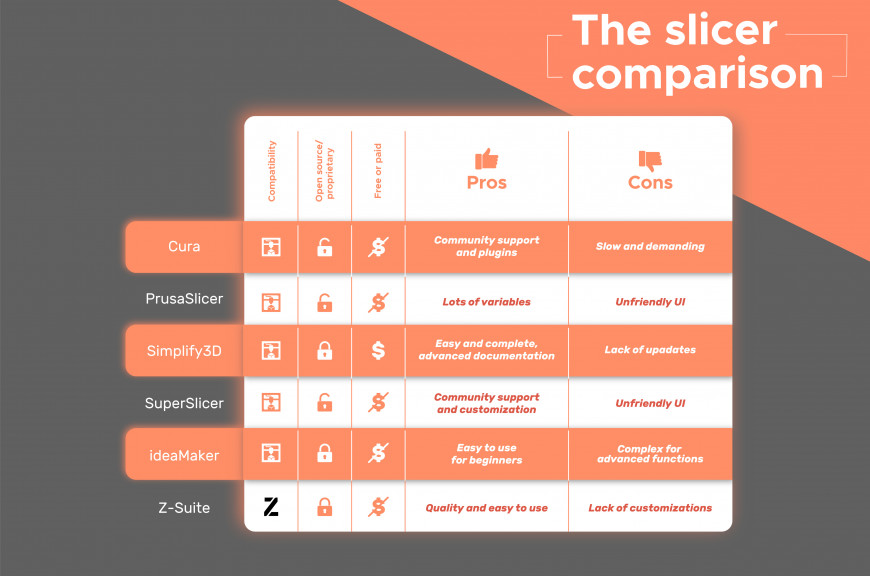

Here you can find a summary table of all the slicers we have talked about, with merits, defects and costs.

If you want to receive presets for FILOALFA® filaments contact us, we will send you the profiles for the slicers created by our Research and Development department.

The main functions

All slicers offer presets for the most common materials and allow you to adjust basic functions such as print speed, cooling and temperature of the extruder and plate. To further improve the quality of your prints, however, you may need to do a few things. If you need some advice on setting the correct temperatures, you can read our article "How to set the correct print temperature" here: Link

The slicer is also responsible for filling the part, not only for its density, but also for the infill design. For more information, you can read the article "How to choose the perfect infill" here: Link

And what slicer do you use for your prints? Do you have other slicers to suggest?