Filled filaments for 3d printing. How to choose?

A brief guide to filled filaments for 3d printing

Carbon fibers, glass fibers, nanotube filled, powders, what are the differences?

Which materials are best suited for my 3D printer?

These are just some of the questions you may have asked yourself about loaded filaments for 3D printing.

Let's try to dispel some doubts, and if you are still left with some questions:

Filled 3D printed filaments, what are they?

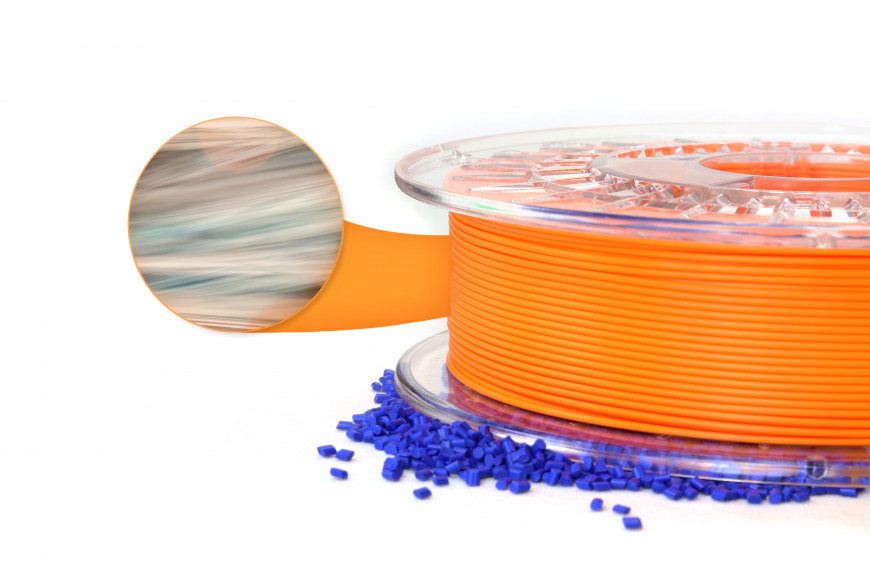

3D printing filaments are made from compounds, or base resins, to which additives (anti-UV, anti-flame, colors, etc.), mineral fillers or reinforcing fibers can be added.

Fillers are mainly natural or mineral powders and fibers that are added to the base resin to give the 3D printing filament its special characteristics.

For example, fillers include calcium carbonate, which is used to give dimensional stability to polymers such as nylon; boron nitride and ceramics for thermal conductivity; metallic fillers for electrical conductivity; and talc and kaolin to increase the elastic modulus of the compound.

Instead, reinforcements are referred to when fibers are added, which can be natural, man-made, or mineral fibers such as glass, carbon, and aramid.

Reinforcements can lower the cost of a compound, dull the surface finish, promote the crystallization of certain polymers, or give them greater technical performance.

In particular, to increase the mechanics of 3D printed parts, efforts are made to add reinforcement in the form of fiber to the base polymers.

Are fibers or powders better? What are the best fillers for 3D printing filaments?

In general, the longer the fibers, the more effective they will be in terms of mechanical and thermal performance. Filaments loaded with fibers and nanotubes give the printed part greater stiffness but make prints more difficult to make.

Short fibers and powders, on the other hand, allow the printed piece to have greater dimensional stability and a high aesthetic finish.

So size does matter! If you are looking for mechanically performing filaments, go for long fibers.

Watch out, though: fillers lower the MFI (Melt Flow Index), which is the value that indicates the fluidity of the material. Don't get caught up in the frenzy of the latest high-speed printers, with loaded filaments it takes patience and longer printing time.

Carbon fibers

Carbon fibers make 3D printed parts more tensile strength and allow you to create lighter prints due to the low density of the carbon fiber and the increased final strength of the part.

Filoalfa filaments are loaded with long carbon fibers to ensure top-notch performance suggest using carbon fiber-filled materials for making sporting goods and automotive parts.

Carbon-filled Filoalfa filaments are:

- AlfaNylon CF

- AlfaTeiko CF

- PP CF

- AlfaOmnia

- AlfaPak 3D

Why choose Alfanylon CF?

ALFANYLON CF is an impact, scratch and chemical-resistant Polyamide (PA) filament. The perfect material for those who want to achieve professional prints with high mechanical and thermal properties while retaining excellent elasticity.

Why choose AlfaTeiko CF?

AlfaTeiko CF is an ultra-high mechanical performance filament suitable for industrial-level prototypes.

Alfateiko CF is resistant to high temperatures, is chemically inert, and resists oils and gasoline, making it an ideal material for the automotive industry.

It is also self-extinguishing, making it ideal for electrical component houses.

Why choose PP CF?

PP CF is an extremely chemically resistant material; in fact, it is not afraid of oils and gasoline. It is not hygroscopic, so it does not absorb moisture from the environment, thus avoiding potential problems at the printing stage and allowing the reel to be used every last inch as if it were new.

PP CF combines excellent printability with high thermal resistance, ensuring the result over a wide range of printing temperatures, allowing the right balance between part definition and adhesion between layers. The perfect material for automotive because it is rigid and inert.

Why choose AlfaOmnia?

ALFAOMNIA is characterized by a high stiffness that accompanies very high mechanical and thermal performance, as well as high aesthetic performance, a matte finish, and with a remarkable ability to "hide" layers. It is recommended for applications requiring very high stiffness and tensile strength combined with ease of printing.

Why choose AlfaPak 3D?

AlfaPak 3D is the recycled filament born from the collaboration between Tetra Pak and Filoalfa. If you are looking for an environmentally conscious filament AlfaPak 3D is for you. Born from the recycling of beverage cartons properly thrown in the recycling bin, this 3D printing filament gives new life to waste. An aesthetic filament that's good for the environment.

Fibra di vetro

Glass fibers make 3D prints more elastic and impact-resistant. In addition, glass fibers are resistant to corrosion and weathering, making your prints perfect for outdoor applications.

Filoalfa glass fiber-filled filaments are:

- PP GF

- ALFA TPU GF

We suggest the use of fiberglass-filled materials for the manufacture of products that must withstand impact (frames) or weathering (yachts and outdoors).

Why choose PP GF?

PP GF is a chemically resistant material with high mechanical properties and good printability.

The high printing temperature range (it has been tested in a temperature range from 230°C to 290°C), allows you to adapt its processing to your needs and your printer, optimizing the adhesion between layers as the temperature increases.

In addition, it is non-hygroscopic: thus potential moisture problems are nullified even during printing, benefiting "shelf life."

We recommend PP GF for uses where aggressive chemicals are present or where high stiffness and dimensional stability are required.

Why choose ALFA TPU GF?

If you are looking for a filament that resists impact and abrasion you will fall in love with ALFA TPU GF.

Thanks to the glass fibers, TPU increases its degree of rigidity, making it an easy-to-print flexible 3D printing filament. Even with bowden-equipped printers, you'll be able to print ALFA TPU GF without any problems.

This is a perfect material for components that must withstand continuous stress, for making gaskets, and ideal for outdoor components.

If you still have doubts about which loaded filament is best for your prints check out our live show made with Help3D (link) or contact us. Our experts will be able to show you the most suitable filament for your creations.